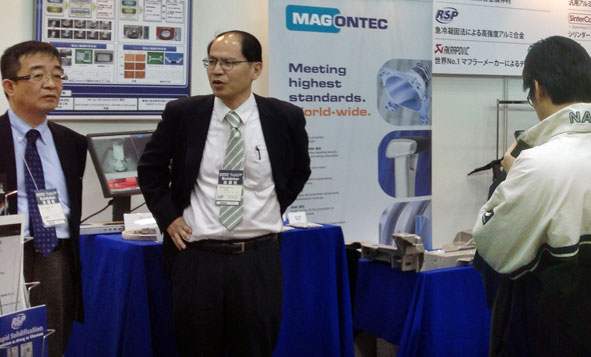

Recent customer solutions in automotive applications, based on Magontec’s magnesium alloys were presented in Tokyo, Japan, early this year. A large number of visitors were highly interested in the components shown at Morimura’s stand, Magontec’s long-term agent in Japan.

As an example of the use of Magontec’s high purity standard alloy AM50, a Volvo instrument panel was shown. It is produced by leading UK die caster Meridian. Two examples underline the outstanding properties on the basis of Magontec’s special alloy AE44. A tunnel cross bracket, casted by Audi for the A8 and an engine cradle for the Chevrolet Corvette Z06 by Meridian, USA, illustrated how automotive parts can benefit from research-driven magnesium alloys.

Dr. Martin Tauber, Vice President of Magontec’s Strategy and Business Development stated: ‘These recent solutions of our customers confirm that magnesium can truly play a significant role in achieving the CO2 reduction targets for automotive companies and they also contribute to the global CO2 reduction frame targets. On this basis, standard and special magnesium alloys from Magontec will contribute towards progress in the next generation of cars. Two important factors in that area are structure and weight reduction. On both, our global research and development team puts its main emphasis.’