Demand for primary magnesium will increase significantly in Europe and the CIS states until 2025. So states a recent study by the renowned TU Bergakademie Freiberg (Germany). The determining factor regarding the increased demand is the ever growing importance of lightweight components.

Fifteen per cent of those asked expect requirements to increase yearly to more than 200 000 t per year, three quarters consider a volume of 140 000 t to 200 000 t to be realistic. Compared with the current demand of around 100 000 t to 110 000 t per year, which is mostly used in die casting, this is a considerable increase. The automobile, metal and foundry industries as well as the research institutions share the prognosis. The strongest growth rate is forecast by the automobile industry.

In competition with aluminium components, magnesium has a high substitution potential. The capability of magnesium to replace a proportion of current aluminium applications by the year 2025 is considered to be high by more than thirty per cent of the group surveyed. Forty five per cent consider the chances moderate. In the automobile industry, over eighty per cent give magnesium a moderate to good chance against steel. The positive expectations are mainly based on magnesium alloys used in die casting applications.

High expectations for new production methods

The experts were also asked about the chances of realizing the global magnesium production projects currently being planned. The clear majority mentioned the joint venture of Magontec and its Chinese partner QSLM in Golmud, western China. Almost sixty per cent sanctioned this plan with regard to its feasibility. The respondents have great confidence in the new plant which is based on the electric melting technology of Norsk-Hydro.

Dr. Martin Tauber, responsible for corporate strategy and development of the Magontec Group, was pleased to state: “The results show a clear confirmation for the association between the outstanding properties of magnesium and the trend towards lightweight construction. The relationship between material and application is perfect. The developments in the market will further benefit from the upcoming capacity increase we are planning for our new plant in Golmud from 2014. Above all, we will be securing a steady, valued supply source for our customers.”

Due to European energy policy, experts expect production rates in the European metal industry to fall slightly on average in future. In contrast, the Magontec plant in Quinghai stands out for its many positive environmental characteristics. For example the carbon footprint of the production of magnesium in connection with the process chain of QSLM is the best in China and even better than that of Aluminium. The project is well on its way. Upon completion, an initial capacity of 56 000 tpa will be available. This can be stepped up corresponding to the electrolytic capacity.

The study ‘Market Development Primary Magnesium 2025’ was carried out by the Technische Universität Bergakademie Freiberg, Germany, under the direction of Prof. Dr. Michael Höck. He holds the chair of Industrial Management and Logistics. 62 experts from Germany were interviewed.

The TU Bergakademie Freiberg is the oldest university of mining science in the world.

Its roots go as far back as 1765. The TU Bergakademie Freiberg concentrates its research and teachings on the economics of sustainable materials and energy and aims them along the raw material and value creation chain.

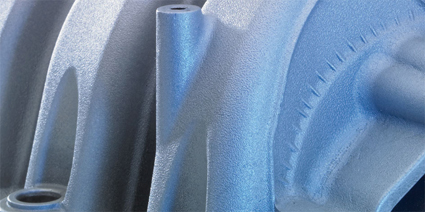

Photo: Magnesium component for lightweight construction in die casting (Detail). © Magontec